Five Axis Machining

Elevate Your Manufacturing with Advanced Five-Axis and Multiaxis Machining

At Prime Machine Inc, we harness the full potential of five-axis and multiaxis machining to revolutionize the way parts are manufactured. By integrating state-of-the-art computer numerically controlled (CNC) technology, we significantly reduce manufacturing time, minimize the risk of setup errors, and unlock the ability to create more complex designs with unparalleled precision.

Transformative Technology for Unmatched Precision

Five-axis machining represents a monumental leap in manufacturing capabilities. Unlike conventional CNC tools that operate on three axes, our five-axis and multiaxis machines introduce additional rotational axes, enhancing flexibility and enabling the tool to approach the workpiece from virtually any direction. This capability not only reduces the need for multiple setups but also achieves more intricate geometries with superior surface finishes.

Why Choose Five-Axis and Multiaxis Machining?

- Efficiency and Precision: Reduce manufacturing time and enhance accuracy, cutting down the need for manual intervention and significantly decreasing the likelihood of errors.

- Complex Geometries: With the ability to rotate around multiple axes, our machines can create sophisticated parts with curved holes and intricate features that go beyond the capabilities of traditional machining.

- Superior Surface Finish: Achieve smoother surfaces by allowing the tool to move tangentially across the workpiece, ensuring a higher-quality finish.

Cutting-Edge Software for Optimal Results

Our commitment to excellence is underscored by our use of premier CAM systems, including Mastercam, along with licensed Unigraphics and ESPRIT software. These advanced computer-aided manufacturing solutions empower us to support the complexities of five-axis machining, ensuring that every part we produce meets the highest standards of precision and quality.

State-of-the-Art Inspection for Uncompromising Quality

Quality assurance is at the core of our operations. Our inspection department employs the latest three-dimensional systems, including laser trackers and Faro arms, in conjunction with Verisurf and PolyWorks software. This allows us to provide detailed reports in both structured data formats and graphical representations, affirming the accuracy and integrity of our manufacturing process.

Experience the Future of Machining

Dive into the world of advanced manufacturing by watching our Five-Axis Machining Video, showcasing the capabilities of our Mori Seiki NT 6600 lathe and illustrating how we bring even the most complex designs to life.

At Prime Machine Inc, we’re not just machining parts; we’re crafting the future of manufacturing. Discover how our five-axis and multiaxis machining services can elevate your projects to new heights of precision and performance.

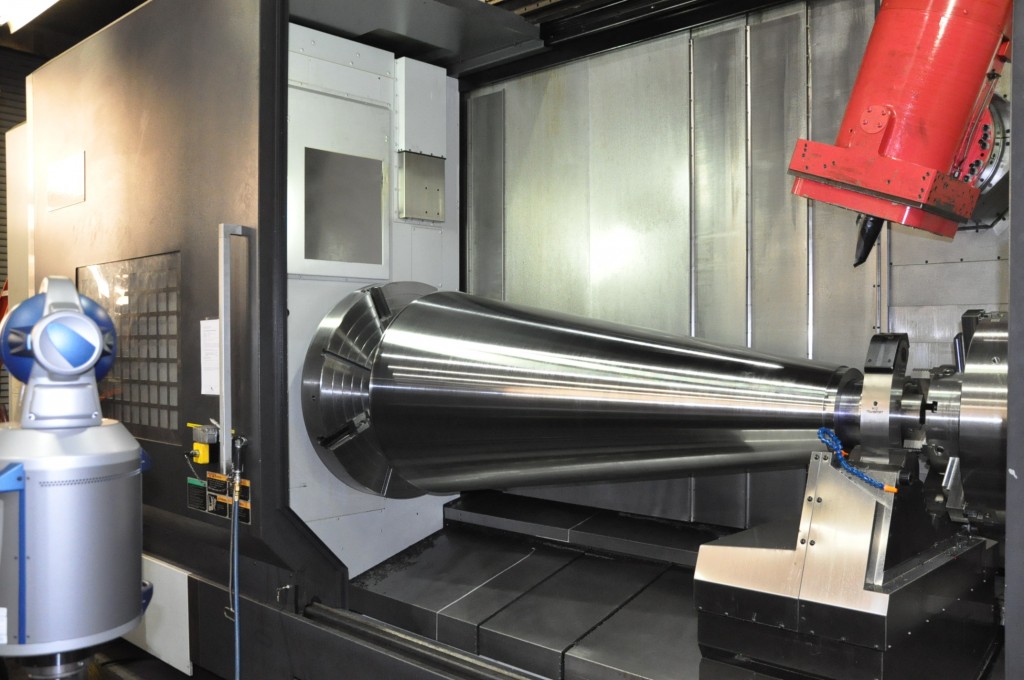

Our Mori Seiki NT 6600 mill/turn lathe using multi-axis machining to create large eccentric shaft.

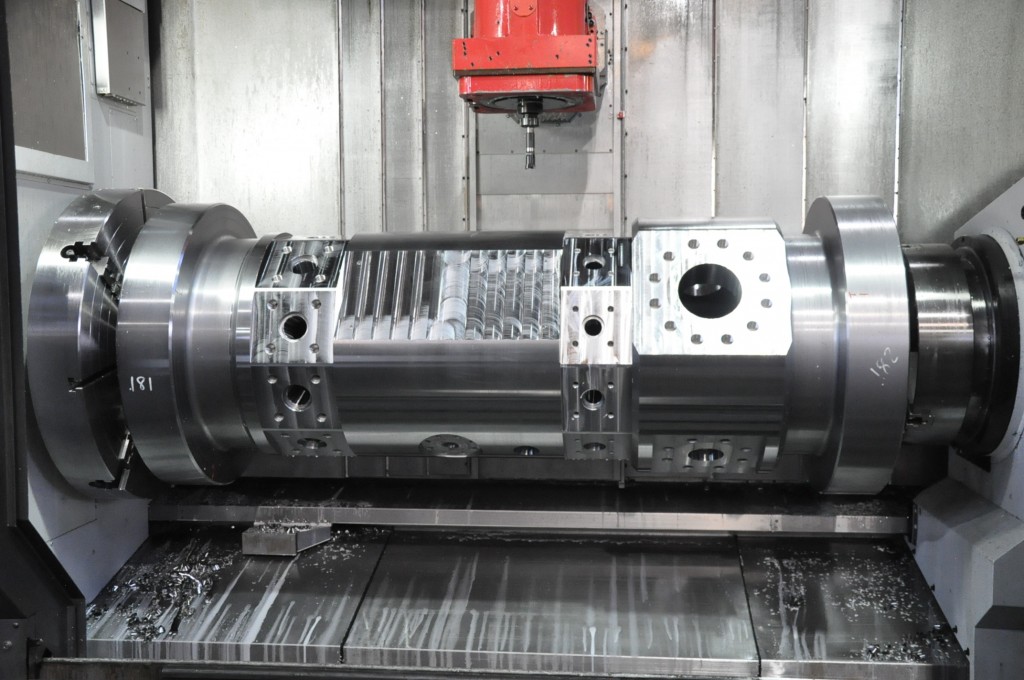

Prime’s Parpas Formula horizontal boring mill with sixty ton rotary table creating a surface on control gate plug.

Horizontal Boring mill with 5 axis capability machining control gate plug.

High tolerance rings manufactured on our Parpas Electra horizontal boring center with full turning table capabilities. Rings required pockets and holes with precision true position requirements.

Our large Horizontal Mill and Turning Center with full five axis capabilities machining of ring that includes turning, milling and drilling of hole all high precision requirements.