Kiln Maintenance

Kiln Maintenance

PMI Advanced Technology Repair Benefits for kiln maintenance- More accurate alignment of all components will absolutely increase lifespan of the entire Kiln and sub assemblies. CAD based reporting and analysis eliminates mistakes in interpreting the problems, and makes any required movements or changes more definite and reliable. Allows for trending and trouble shooting with high speed and detail. Saves precious downtime by individual component inspection and whole unit geometry checks. Allows for many operations to be done in advance of outages, with confidence of fit up in time of outage need. Precision laser tracker measurements for setting and squaring of trunnions. Tires completely manufactured. Gears reversed or replaced. Kiln maintenance we have the millwrights, welders, machinists and the equipment needed.

Machining large kiln riding ring section on our vertical mill

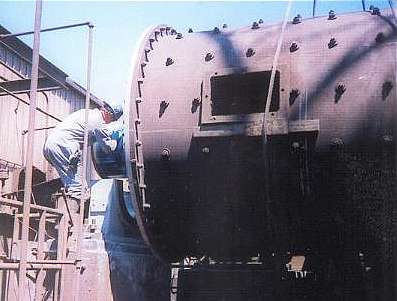

Trunion grinding, tire grinding, alignment, shell repairs, manufacture new components are all part of services for Kilns.

Our in depth ISO qualified repair procedures insures quality repairs / rebuilds.

Full in house machining and fabrication means rapid turn around.