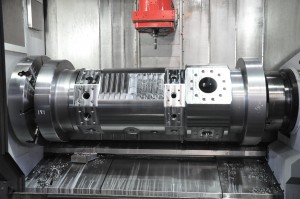

Oil & Gas equipment repairs and manufacturing

Prime Machine Inc. has thirty plus years experience serving the oil and gas industry.

Providing machine shop, welding, millwright service and replacement parts.

Rebuilding large industrial engines integral to compression and generation units. Compressors both centrifugal and reciprocating rebuilds. We have an excellent safety record EMOD below 1. We are AS9100 and ISO 9001 certified shop. Welding certifications “U”, “R”, “S” stamp certifications for welding. Craftsmen have MSHA and OSHA certifications of safety training.

Complete laser inspection of cat engine block. Measuring size and geometry of bores, pan rail flatness, firing deck surfaces with Faro laser tracker. |

|