Prime Machine Shop Large Machining of Complex Multi-Axis CNC components that require Turning and Milling Operations.

Prime Machine Inc.: Large Machining with Precision CNC Machine Shop and state of the art Turning, and Milling Services

Welcome to Prime Machine Inc., where our state-of-the-art machining capabilities bring your engineering visions to life. Our facility is renowned for handling complex, large-scale machining projects with unmatched precision and efficiency.

Advanced Large Machining Services for Superior Results

- Comprehensive CNC large Machining: At the heart of our operations lies our CNC machining prowess, featuring advanced turning, milling, and multi-axis capabilities. Our technology-driven approach ensures we can tackle the most intricate projects with precision.

- Large Component Expertise: Specializing in large and heavy components, our shop is equipped with cranes that handle over 50 tons, allowing us to manage even the most challenging tasks effortlessly.

- Unparalleled Accuracy and Precision: Our unique combination of skilled machinists, laser tracker technicians, and state-of-the-art laser equipment for machine geometry verification ensures we achieve exceptional accuracy over large distances. We build bridge size components to watchmaker tolerances.

- Expert CNC Programmers: Our CNC programmers are at the forefront of technology, adept at crafting precise geometrical features required by today’s innovative projects.

- Comprehensive Inspection and Verification: Our inspection team utilizes the latest in data reporting, including structured data, graphical, and tabular formats, to ensure every machined profile meets stringent quality standards.

Certification and Quality Assurance

Prime Machine is proud to be certified under AS9100:2009, JISQ 9100:2009, and ISO 9001:2008, underscoring our commitment to quality and precision. Our rigorous quality systems guarantee that every component we produce meets and exceeds customer expectations.

Our Commitment to Excellence

From bridge-sized components to watchmaker precision, Prime Machine’s world-class capabilities ensure we deliver only the best. Our ability to verify results with such a broad range of tolerances sets us apart as a leader in the industry.

Discover Large Machining Excellence with Prime Machine

We invite you to explore our large machining expertise through our featured video: [Large Machining at Prime Machine]. Dive deeper into how our cutting-edge capabilities, commitment to quality, and meticulous attention to detail make us the preferred partner for your machining needs.

Large CNC horizontal milling with rotary table and 5 axis capabilities.

Machining large ring on Parpas Formula multi-axis horizontal machining center with rotary table. Our machine shop has the largest machines west of Mississippi river all with precision accuracy and trained operators

Parpas Electra five axis large machining horizontal with turning capability

Large Horizontal Mill and Turning Center with full five axis capabilities. Turning table three meter, sixty revolutions per minute, forty tons load capacity. These machines and the craftsmen produce high quality machine shop parts.

Large machining on Mill/turn CNC five-axis machining center. Machining eccentrics on crank shaft.

Machining large crankshaft with our multi-axis CNC lathe. Turning and milling of crankshafts are accomplished in one machine.

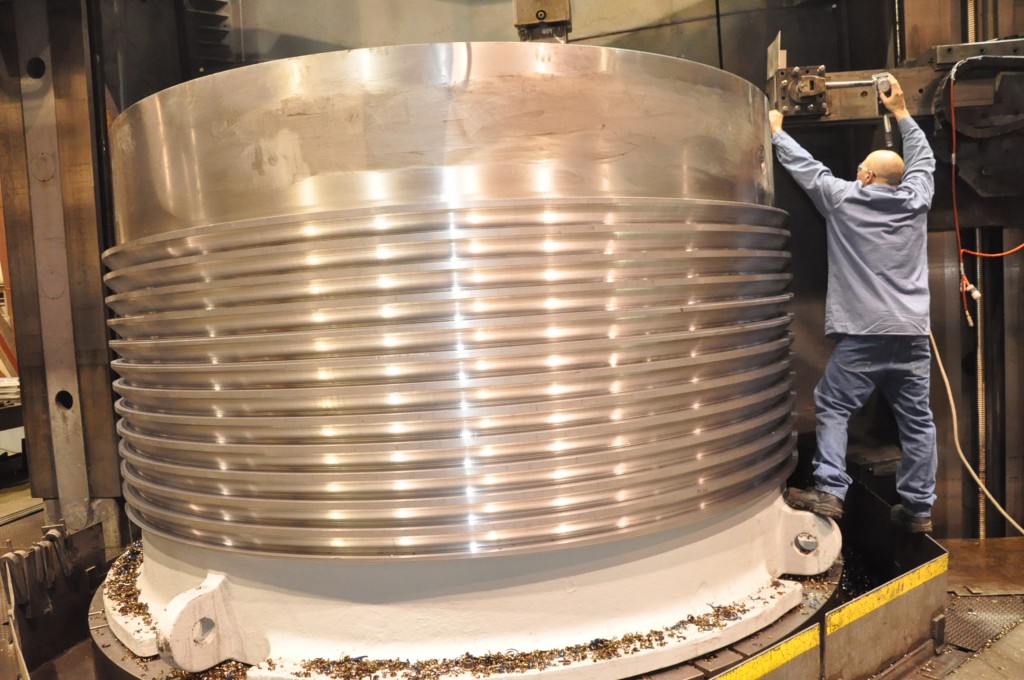

Large vertical CNC turning center machining threads on bowl.

Precision machining of an adjustment bowl designed for large cone crushers, showcasing expert craftsmanship and advanced manufacturing techniques to ensure optimal performance and durability in our machine shop.

Milling engine block on large vertical large machining center.

Prime Machine machining large engine block on Rottler vertical milling center built and tooled to complete all requirements for machining of large blocks both engine and compressor. Engine machining in our state-of-the-art machine shop: Precision work on a large diesel engine block to ensure top performance and durability.”

Large vertical turning center machining upper head for hydro unit.

Hydro Electric turbine Machining of a lower wicket gate bearing ring on large vertical CNC turning center with live tooling for boring. Prime Machine shop large machining of complex part.

Large Horizontal lathe machining (turning) induced draft fan shaft.

Large Industrial fan shaft being machined in Prime machine shop Niles Lathe. This is very large machining that requires high quality surfaces and precise sizes.

Large portable lathe machining screen drum on site work.

Turning screening drum 22 feet diameter, 50 feet length, weighing 386,000 pounds in Prime Machines portable lathe. On site machining of a grand scale. Truly world class.