Code Welding ASME and AWS

Code welding design and build shop and field.

Prime has a “U” stamp authorizing the manufacture of pressure vessels at our location or in the field in accordance with the provisions of the ASME Boiler and Pressure vessel code for code welding.

Prime has a “S” stamp certification authorizing the manufacture and assembly of power boilers at our facilities an in the field in accordance with the provisions of the ASME boiler and pressure vessel Code.

Prime has an “R” stamp certificate of Authorization for the metallic repairs and/or alterations at our facility and extended for field repairs or alterations in accordance with the ASME boiler and pressure vessel Code.

Additionally we are certified and qualified to the AWS American Welding Society codes.

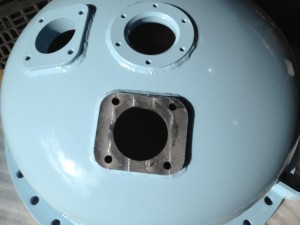

Completely integrated shop with weld fabrication, machining and installation of equipment over 35 years experience. Welding of all kinds of material aluminum, titanium. stainless steel, cast iron and all the steels.

Our capabilities include MIG, TIG, Sub-Arc and stick welding. We have the tooling: large position capability, rolling, shear, punch, CNC burning, with large crane capacity for handling large parts. Uniting large machining and large fabrication make us unique in our ability to build large precision products.