Industrial Engine Machining and Repair

Welcome to Prime Machine Inc: Premier Industrial Engine Machine Shop

At Prime Machine Inc, we specialize in providing top-tier industrial engine repair and machining services. Located in the heart Salt Lake City, our state-of-the-art facility is equipped to handle all your engine machining needs, ensuring your machinery operates at peak performance. With years of experience serving various industries, we understand the critical importance of precision, efficiency, and reliability in every job we undertake.

Our Expert Services

Comprehensive Engine component cleaning:

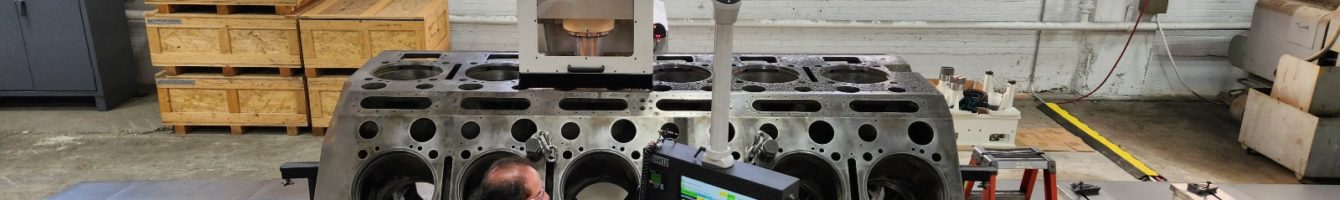

Prime Machine laser tracker technician measuring features on large engine block for a complete inspection of line bore, deck surfaces heights, and other critical features.

Advanced Machining Capabilities:

Optimize your large engine component needs with our specialized reverse engineering and manufacturing services. Our expertise shines in handling obsolete and hard-to-find engine parts, such as crankshafts, connecting rods, pistons, camshafts, and heads. By harnessing the power of advanced technologies and our extensive experience, we stand out in creating and manufacturing components that you can’t find on the market anymore.

Our process starts with a thorough analysis of the original parts. We use precision measurement tools and 3D scanning techniques to capture every detail with utmost accuracy. This dedication to precision allows us to craft exact replicas of the original components or even enhance them for better performance and durability. Whether your goal is to revive a vintage engine to its peak condition or to maintain a critical piece of machinery, our team commits to delivering solutions tailored to your unique requirements.

We’re not just about making parts; we’re about ensuring your engines operate smoothly, efficiently, and reliably. Our commitment to quality and our passion for engineering excellence mean that no matter how rare or obsolete your engine components are, we’ve got you covered. From custom fabrication to repairing existing components, we guarantee your engine’s components are in the best possible condition.

Let us help you keep your engines running like new. With our blend of advanced technology, expert knowledge, and dedication to quality, your engine components are in skilled hands. Whether it’s for restoration or maintenance, our specialized services are designed to meet and exceed your expectations, ensuring your engines continue to perform at their best.

Reverse engineer and manufacture new connecting rod.

Field machining of engines:

- Field machining of engine block for new sleeves by Prime Machine skilled on site machinists.

- Unmatched Expertise: Our team of experienced machinists and mechanics possess the knowledge and skills necessary to tackle the most challenging engine issues.

- State-of-the-Art Equipment: Our facility is outfitted with cutting-edge machinery, allowing us to perform precise and efficient repairs and machining.

- Quality Assurance: We adhere to the highest standards of quality, with rigorous inspection processes to ensure every repair and part meets your exacting requirements.

- Customer-Focused Service: We understand downtime is costly. That’s why we’re committed to providing prompt, reliable service to get your operations back up and running as quickly as possible.

Our Commitment to Excellence

At Prime Machine Inc, we’re not just another machine shop. We’re your partners in maintaining and enhancing the performance of your industrial engines. Our commitment to quality, precision, and customer satisfaction drives us to deliver the best possible service, tailored to your unique needs.

Get in Touch

Ready to experience the difference that professional, reliable engine machining and repair can make for your business? Contact us today to discuss your needs, and let us show you how we can support your operations with our expert services.