Field Machining On Site at Plant

Field Machining turning or milling world class capability.

Our field machinists are skilled craftsmen that have been trained and are experienced in the trade of field machining components on the plant site. Safety is always of first concern and most of them have multiple certifications of safety training including MSHA, OSHA and UITC. Their technical knowledge of rigging, machine setup, alignment, and machining processes are exceptional. Work site organization and meeting schedules are priorities. Additionally we are equipped with the best tools and trained to use them.

World Class field machining of Krupp Polisius screening drum. Prime designed and built portable lathe to turn the screen drums 22 feet in diameter by 60 feet in length weighing 386,000 pounds. Our process create a more accurate part with flanges parallel as opposed to machining several sections assembling them together and having accumulated errors.

After machining of flanges they were measured with laser tracker to determine flatness and parallelism. There are only one or two companies in world could accomplish major field machining operations.

|

Boring upper sleeve area and install new sleeves engine block in field at gas plant saving the cost and time of removing engine and sending to a large machine shop.

Machining ball mill shell face with large milling machine designed by Prime Machine. Work was done in artic circle end of ice road.

Milling the face of ball mill shell. Work was done in arctic circle.

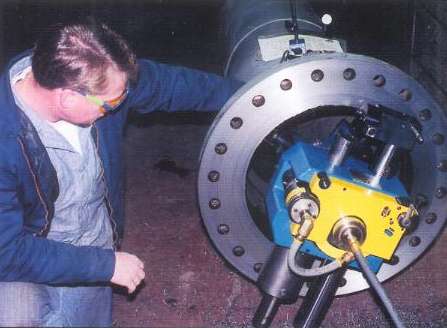

Field machining heat exchanger flange on site with climax flange facer.

Line Bore machining pin fits on site Shove in mine.