Babbitt Bearings

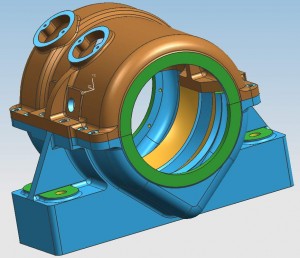

Prime Machine specializes in Babbitt bearings. Our capabilities include both centrifugally cast and statically cast of Babbitt bearings. Our spin fixture is capable of spinning bearings weighing 10 tons and 150 inches in diameter. Our proprietary methods allow us to achieve 100% bonds and porosity free bearings. All bearings are checked dimensionally using three dimensional measurement technology to verify both bore and housing fits. Radial load, thrust, tilting pad bearings are all rebuilt by Prime craftsmen experienced in providing quality products.

We repair and rebuild all types of Thrust, Sliding, and Radial Babbitt Bearings:

Centrifugally casting babbitt bearings & Ultrasonic testing of bond.

|

Centrifugally casting of hydroelectric turbine babbitt bearing with 54″ journal. |

Full in house Pouring, Machining, and Inspection means rapid turn around.

Mill babbitt bearing rebuild. Bearings are measured on arrival and housing fits verified. Bearing cast to provided maximum bond strength and no proisity. Machined to size, inspected, and packaged for shipping.

Types Of Babbitt Commonly used

Babbitt has good load carrying capacity between 800 PSI and 1500 PSI Maximum operating temperature for Babbitt is 300º F. In motors 180º F to 190º F is considered running hot. Some turbine applications run as high as 225° F. Many technicians however, will set the alarm at 185º F and trip at 205º F. Melting temperature for common Babbitt varies from 350º F to 475º F bullet Special bonding techniques are required to metallurgically bond Babbitt to metal. Tin based Babbitt (#2) is approximately 89% tin with the remainder being antimony and copper. The hardness of this alloy gives excellent load-carrying characteristics. Lead based Babbitt (#7) is 75% or more lead. Conventional lead- base Babbitt contains antimony and tin, which greatly increase the strength and hardness of lead. This alloy is fully adequate for lower loads and moderate temperatures.

| Tin Based Babbitt | ||||||

| Composition of Babbitt Lining | Load VS Temperature | |||||

| ID | % Sn | % Sb | % Pb | % Cu | 68° F | 212° F |

| #1 | 91.0 | 4.5 | 4.5 | 4400 | 2650 | |

| #2 | 89.0 | 7.5 | 3.5 | 6100 | 3000 | |

| #3 | 83.3 | 8.3 | 8.3 | 6600 | 3150 | |

| #11 | 87.0 | 7.0 | 6.0 | |||

| Lead Based Babbitt | ||||||

| Composition of Babbitt Lining | Load VS Temperature | |||||

| ID | % Sn | % Sb | % Pb | % Cu | 68° F | 212° F |

| #7 | 10.0 | 15.0 | 75.0 | 3550 | 1600 | |

| #8 | 5.0 | 15.0 | 80.0 | 3400 | 1750 | |

| #13 | 6.0 | 10.0 | 83.5 | 0.5 | ||

| #15 | 1.0 | 16.0 | 82.4 | 0.6 | ||